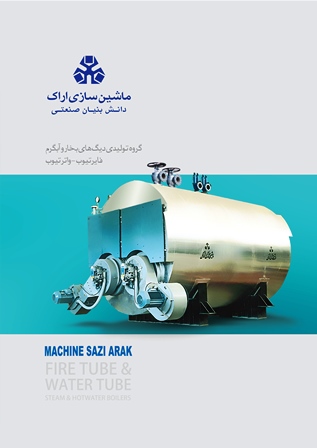

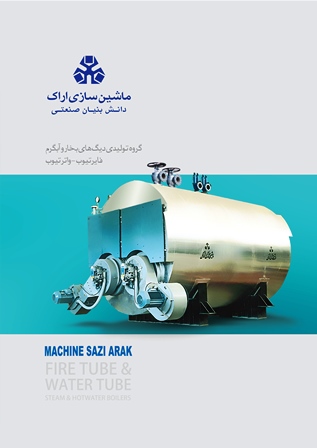

Machine Sazi Arak Co. (MSA), the first and the biggest designer and manufacturer of steam boilers and hot water boilers in Iran and the Middle East, with more than 40 years of dazzling experience and enjoying the services of more than 2500 skilled work force, modern equipment and drawing on the findings of its Training Center and Industrial Research has always been trying its best to manufacture high quality products in line with the latest technological advances. Our products have so far found their way to the domestic markets and different markets abroad.

Radiography, ultrasonic and penetrating liquid tests are performed under the supervision of quality control (QC) inspectors on the welding lines. The stress relieving operations of the boilers are carried out in 600±20 conditions resulting in the uniformity of the microscopic structure in pressure parts and the elimination of the remaining stresses of different processes such as rolling, fabrication and welding. Hydrostatic test is done as per BS2790 standard and 1 .5 times design pressure after tubing. In final step, the burner will be tested about 24 hours. The quality and standard certificates are issued for each boiler after checking all controllers and indicators.

All the designs used in this factory have been approved by TUV Co. (Austria).

Single burner boilers in low and medium capacity (click to see)

Boiler type : FIRE-TUBE (WETBACK)Hot Water BOILER

Designing standard: bs2790-1992, EN 12953

Material standards:

Plates: bs1501-151GR.430A and EN 10028

Tubes: EN 10216 PART1H.F.S & BS3059

Stay bars: EN10222

Radiography: based on BS-2790, EN12953 standard.

Working pressure: up to 450 psi or according to customer order

Hydrostatic pressure test: 1.5 times over designed pressure

Steam temperature: saturated temperature is 185 OC in 150 psi.

Steam temperature of super heater: 350 OC

Electrical power consumption: 3phase, 380v, 50Hz.

Burner type: Ham worthy model and / or other types will be

Installed by customer order, multi fuel consumptions.

Fuel type: gasoil, heavy fuel oil, NG (Natural Gas)

Valves and controllers: vent valve, blow down valve, main steam stop valve, feed check valve(s), sampling valve, water level controllers, water level gauges, pressure switches and safety valve(s)

Electrical panel is fully automatic and equipped with various audible and visual alarm systems such as: indicating lights, low water level alarms, miss firing of burner, and in case of opening the electrical panel door for any reasons the burner would be shut down.

Stress relieving at 600+ _ 20 oC

Twin burner boilers With high capacity (click to see)

MSA boilers benefits

Small size, high efficiency, easy installation& starting up as well as transportation.

Applying the latest authentic standard in designing and materials.

Quality control (QC) and quality assurance (QA) in all fabrication procedures.

All process will be supervised by 3rd party insurance during manufacturing.

Free operational and maintenance courses in MSA Co. training complex.

Availability of spare parts and after sales services from authorized agencies.

Engineering consultation in optimal selection of boilers.

Equipped with safety and alarm systems.

Ability of reaching to the final efficiency by changing the working pressure.

Capability of installing super heater system for producing dry steam based on order.

Ability of installing economizer to increase efficiency.

Stress relieving at 600+ _ 20 oC

Corrugated furnace

Material supply from Western Europe

Download our catalogue for more detailed information

|